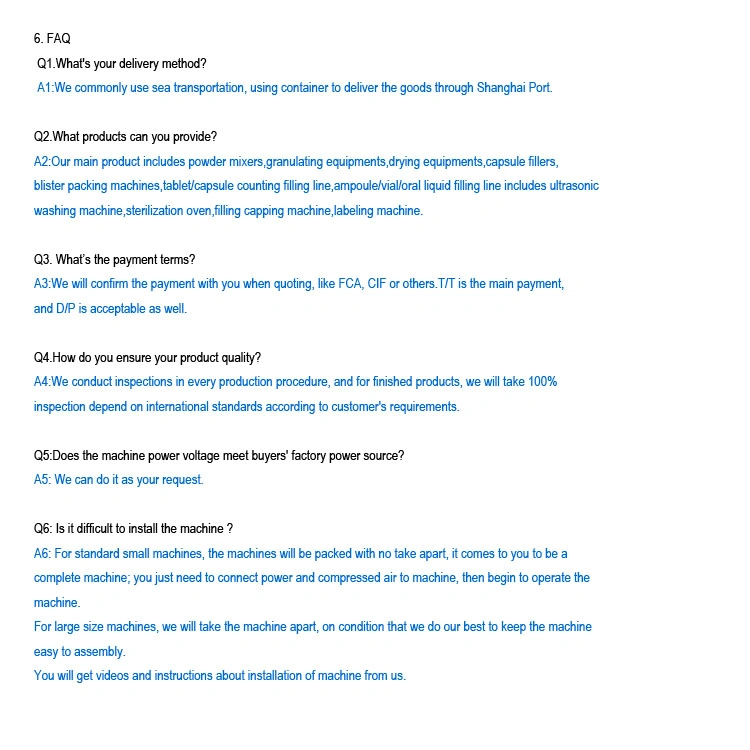

Basic Info.

Model NO.

SJB-02

Seals Mode

Trilateral Seals

Speed

Medium

Continuous-Rolled

Yes

Sealing & Cutting

Heat-Sealing Heat-Cutting

Layer

Single

Machine Type

Bag Forming Machine

Computerized

Computerized

Type

Non-Woven Bag Making Machine

Brand Name

Unimach

Filling Range

3-15ml

Capacity

30-50(Bag/Min)

Inner Bag Size

W: 60-80(mm) L: 40-80(mm)

Tag Size

W: 25mm L: 18-22mm

Thread Length

155mm

Total Power

220V/50Hz /3.5kw

Dimension(L*W*H)

780*940*1800mm

Net Weight

400kgs

Transport Package

Wooden Case

Specification

HB-SJB02

Trademark

UNIMACH

Origin

China

Production Capacity

100sets/Year

Product Description

Wholesale Ctc Tea Filling Packaging Machine with Triangle Bag and Envelop

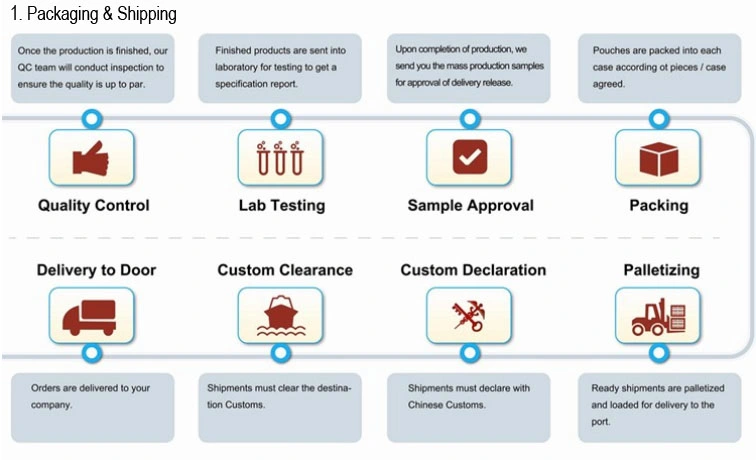

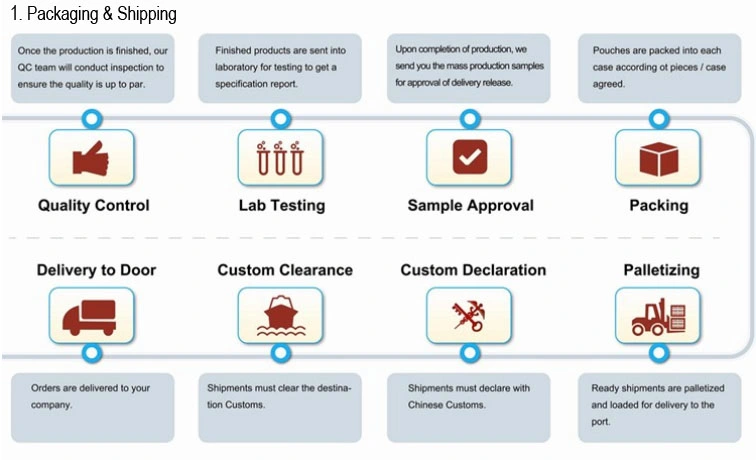

1. APPLICATIONS:

Be used for automatically packing products as green tea, black tea, flower tea, health tea, medicine tea, and granule and so on.

2. FEATURES:

1. This unit can perform either three sides sealing or triangle teabag .just need single bond to change the bag between three sides sealing and triangle shape,

2. Packaging capacity: 3000bags/hour (Determined by packing material),it adopts ultrasonic sealing for tea bags,

3. Applicable packing materials: Nylon film with thread and label,

4. The precision electronic scale metering(2 heads of linear weigher) way very easily in the transformation of filling material,

5. Human-Computer Interface, Omron PLC control, adopted the Panasonic double Servo motor to make the bag .Supplied complete setting functions. Easy operating,

6. Main motor overload protection device,

7. Packaging material tension automatic adjustment device,

8. The machine will automatically stop when issued the warning.

1. This unit can perform either three sides sealing or triangle teabag .just need single bond to change the bag between three sides sealing and triangle shape,

2. Packaging capacity: 3000bags/hour (Determined by packing material),it adopts ultrasonic sealing for tea bags,

3. Applicable packing materials: Nylon film with thread and label,

4. The precision electronic scale metering(2 heads of linear weigher) way very easily in the transformation of filling material,

5. Human-Computer Interface, Omron PLC control, adopted the Panasonic double Servo motor to make the bag .Supplied complete setting functions. Easy operating,

6. Main motor overload protection device,

7. Packaging material tension automatic adjustment device,

8. The machine will automatically stop when issued the warning.

3.TECHNICAL DATA:

| Item | Content |

| Capacity | Max.50bags/Minute (Determined by packing material) |

| Filling precision | ≤±2% (Determined by packing material) |

| Bag size | 60-80(W)*40-80(L) mm |

| Packing film | 120 mm,140 mm,160 mm |

| Sealing type | Triangle bag and flat bag |

| Filling range | 1-7g |

| Film thickness | 0.04-0.06mm |

| Packing material | Nylon, Polyester net non-woven fabrics, ultrasonic sealing materials |

| Rolled outer diameter | ≤400 mm |

| Rolled paper core inside diameter | 76 mm |

| Air consumption | 0.6Mpa 0.4m3/min |

| Total power | 2.2KW |

| Power | Single 220V,50Hz |

| Air compressor | less than 1 cube |

| Dimension | 780* 940*1800mm |

| The weight of the machine | 400kg |

Bag samples:

triangular bag conveying bucket packing machine

I. Applicable to:

This machine is suitable for nylon triangle bag packing.

II. Features:

The three sides of the bag are sealed, and the bag is beautiful in shape.

The machine has the functions of automatic bag making, measuring, filling, sealing, cutting, counting, printing batch number and so on.

And the use of advanced microcomputer controller, drive stepping motor control bag length and trademark positioning.

The machine is stable in performance, accurate in detection, and has little error in intelligent control. The function of date printing, oscillating blanking and easy to tear can be accomplished by adding accessories.

III. Technical parameters:

And the use of advanced microcomputer controller, drive stepping motor control bag length and trademark positioning.

The machine is stable in performance, accurate in detection, and has little error in intelligent control. The function of date printing, oscillating blanking and easy to tear can be accomplished by adding accessories.

III. Technical parameters:

| Bag size | Film width: 80-130mm |

| Bag length: 85-150mm | |

| Packing speed | 25-35 bags/min |

| Measurement range | Triangular bag |

| Electricity | 220V ~ 50Hz |

| Machine weight | 300KG |

| Machine size (Length × Width × Height) | 900 × 700 × 1700 mm |